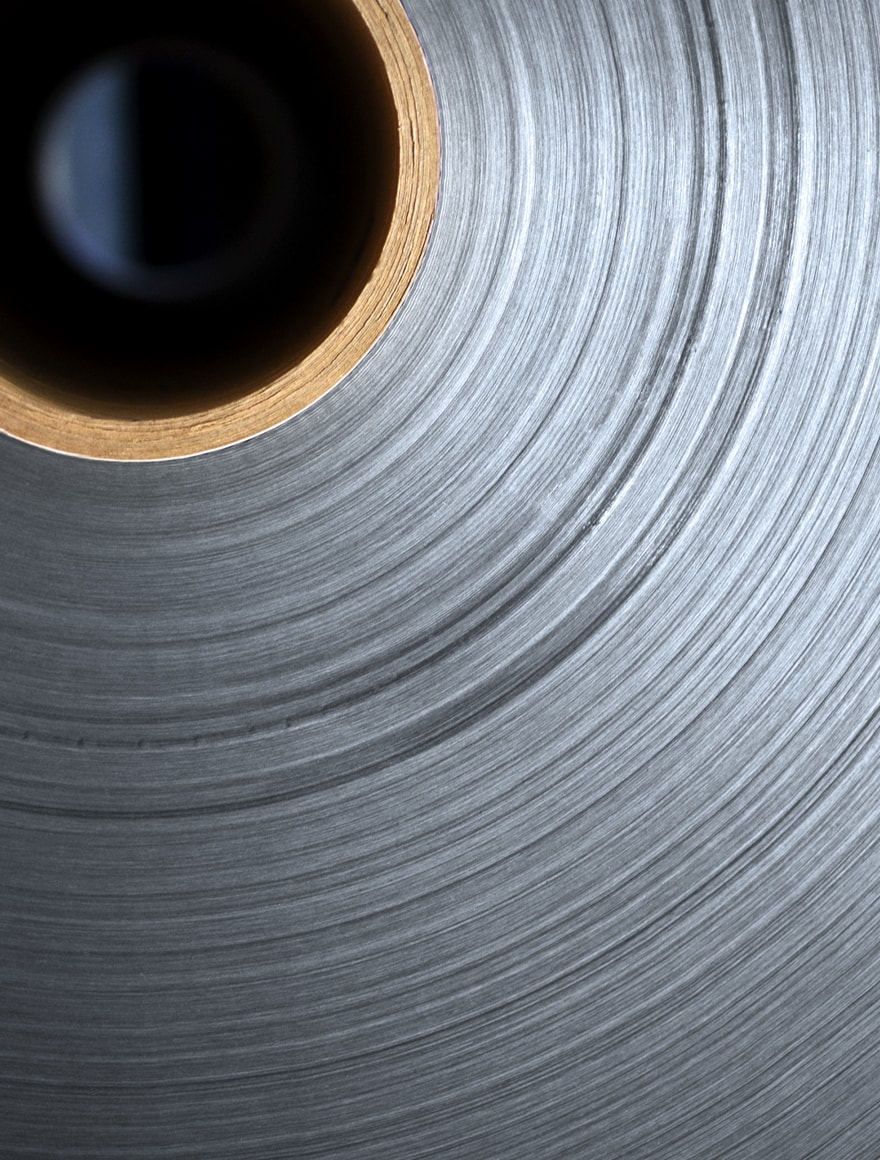

03. Laminating area

Maximum performance, minimum thickness

Ultra thin multi layered films

High-quality solvent-free lamination

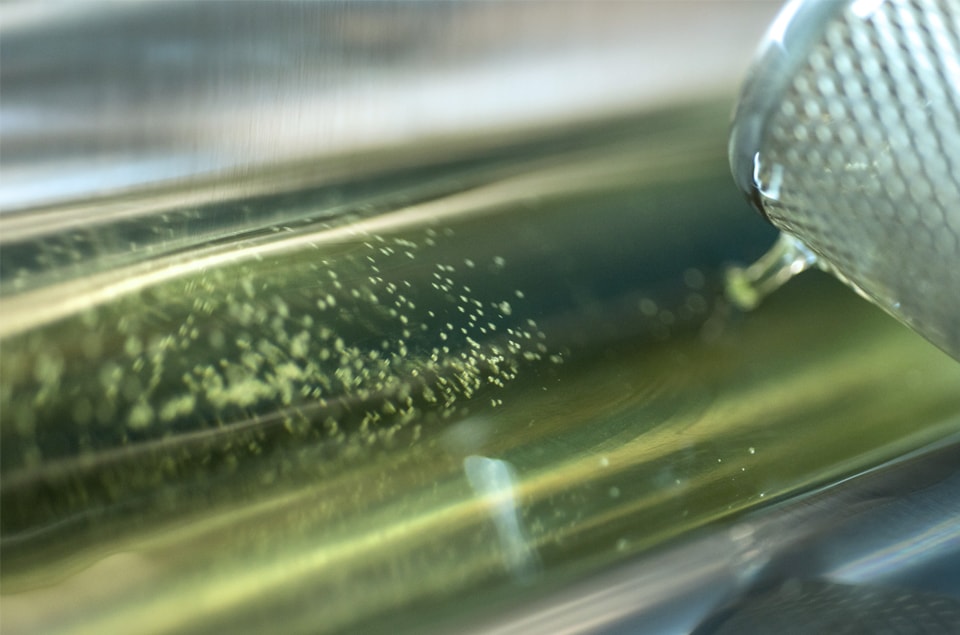

We ensure the highest barriers against UV rays, oxygen and moisture, with minimum thickness. We employ fully recyclable materials such as PET and we only use solvent-less adhesives. We have created a clean and safe working environment to offer the best to our employees and our customers.

BARRIERS

The right structure to protect your product

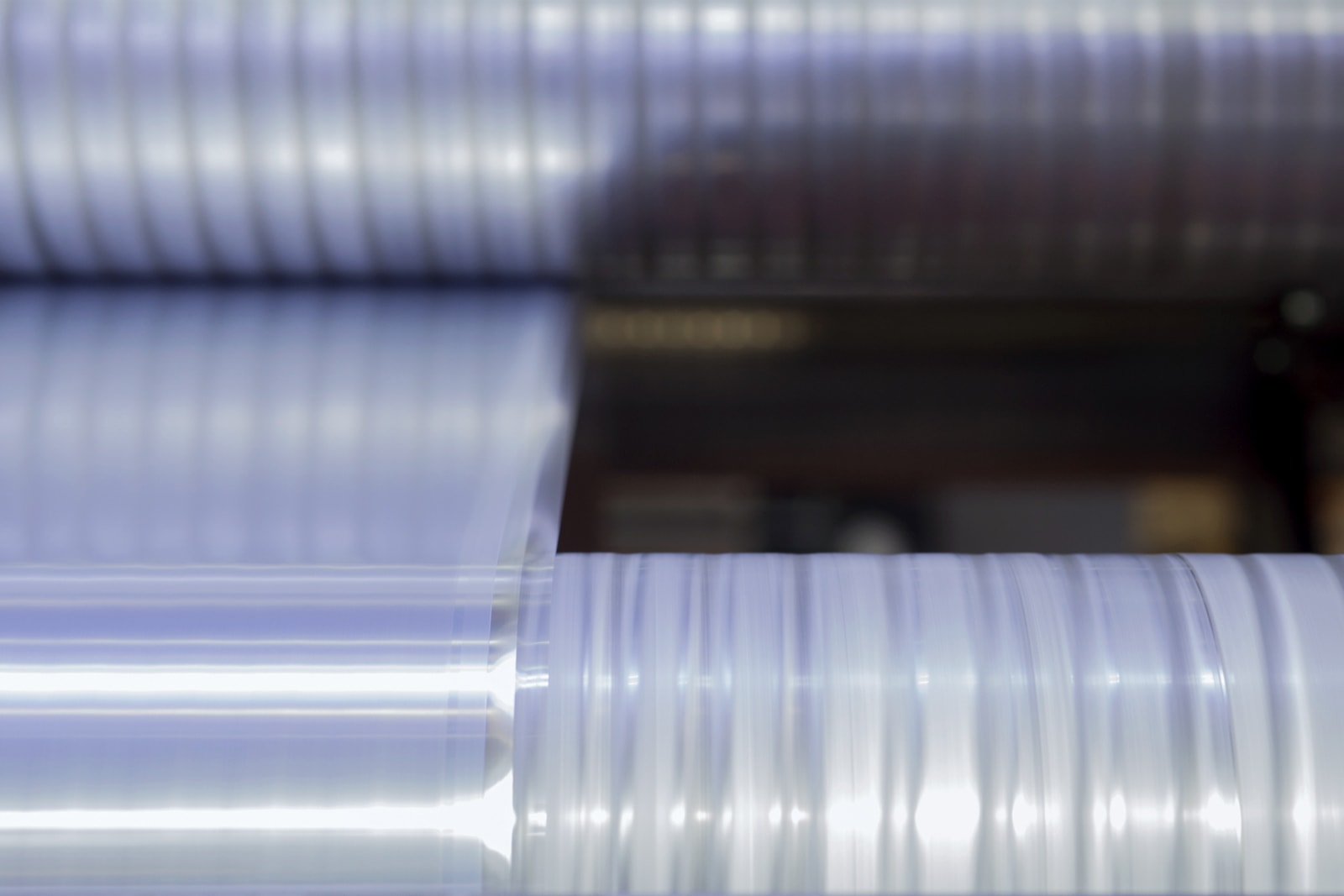

Our laminated films are provided with high barrier and protection. Each layer of the structure is composed of a specific material that has a particular role and affects the performance of the final product. ACM uses various materials depending on the customer’s specific needs, creating single and multiple layers films, with UV barrier, antifog and EVOH.

OUR MATERIALS

Polypropylene extruded ( PPCAST )

Polypropylene coextruded ( PPCOEX )

Polypropylene bioriented ( PPBX )

Polyethylene ( PE ): low, medium and high density

Polyester ( PET )

Bioriented polyamide ( PABX )

Nylon extruded ( PACAST )

Aluminium ( ALU )

Paper